Projects

Earl Turcotte Waste Transfer Facility

Effort Trust

Innovation Hub

Miller Peppel Stone Transfer Station Whitby

Press Pit

TTC McNicoll

Waterloo Memorial Recreation Complex

Garage Restoration – 50 Queen Street, Kitchener

Jacob’s Retirement Home Beamsville

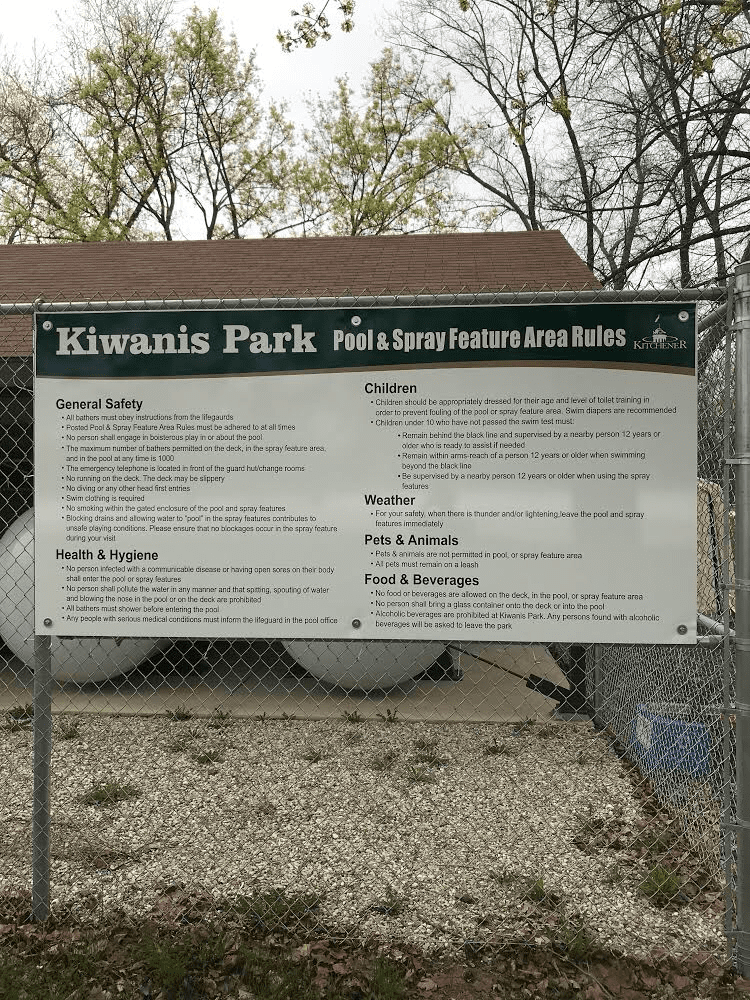

Kiwanis Pool

Loblaws Restoration

MTO 2017-3029 – Scotland Drive Bridge Repairs

AVRIL Building

Bridge # 7 Rehabilitation

Caledonia Mill

Galt Wastewater Treatment Plant

Jacob’s Retirement Home Beamsville

NRC

Oxford County Sewage Pumping Station

Piller’s Brantford

Riverside Exhibition Centre

Galt Wastewater Treatment Plant

Nature Fresh

New Beverly Central Elementary School & COH Community Centre

Whitby Health Centre

Copper Road Salt Dome

Dundas Street Reconstruction

Garage Restoration – 50 Queen Street, Kitchener

Kettle Creek Public School

The Gaslight Condos

Garage Restoration – 50 Queen Street, Kitchener

Job Name: Garage Restoration – 50 Queen Street, Kitchener

Contractor: Brick & Co

Owner: Undisclosed

Engineer/Architect: K Smart

Background:

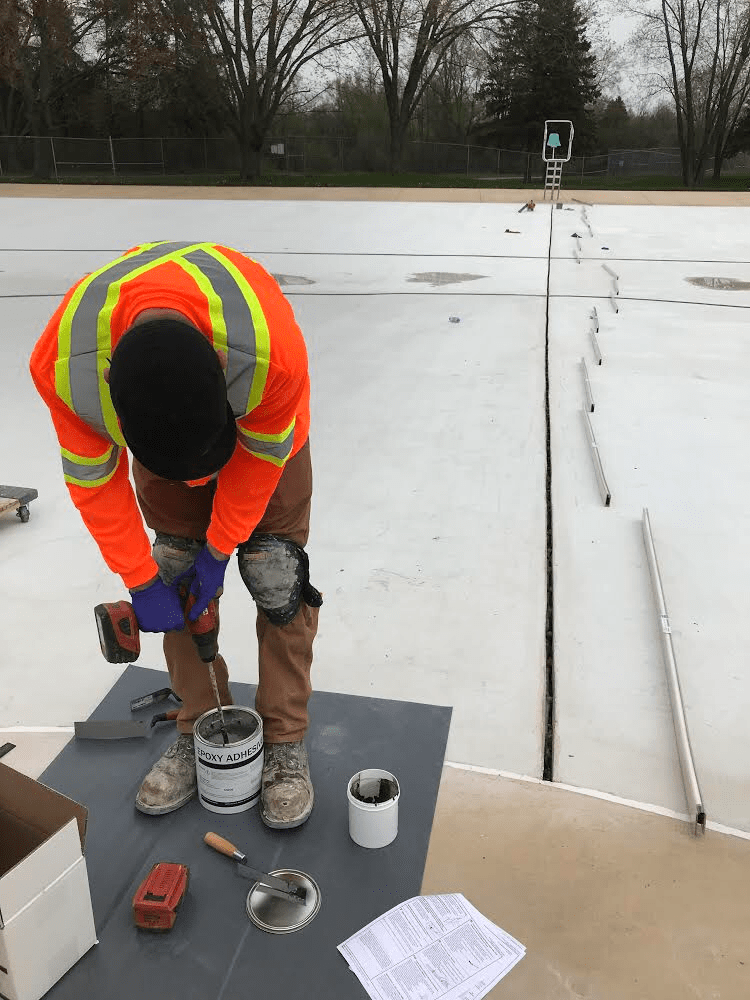

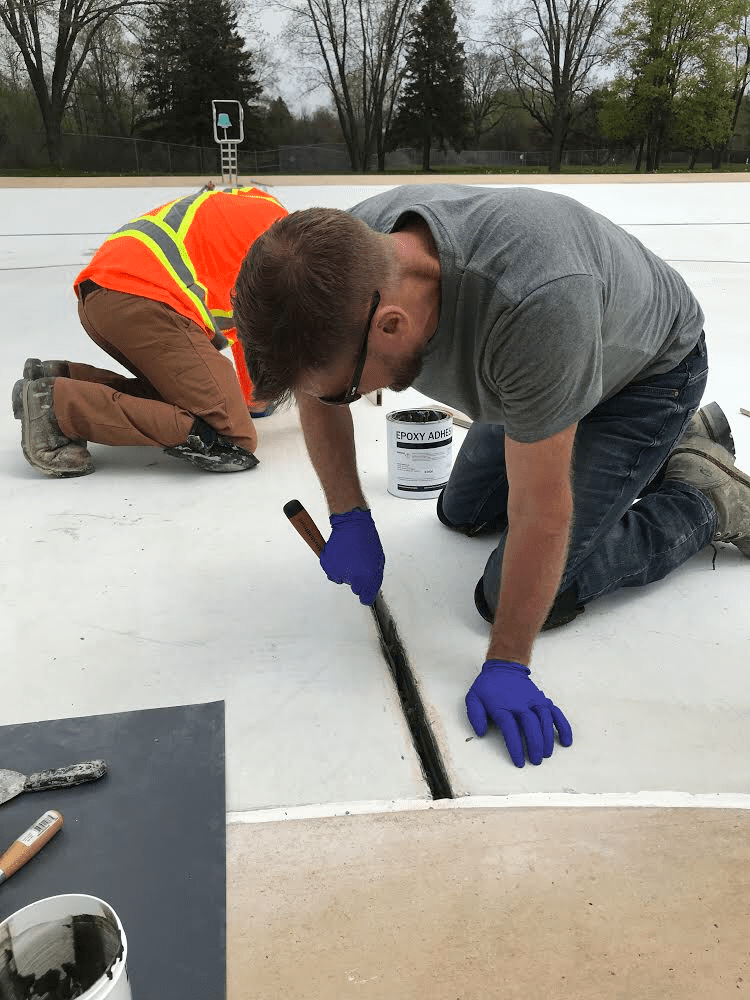

Sections of the parking garage at 50 Queen Street, Kitchener were leaking water, necessitating remediation. The split-slab waterproofing membrane installed at the time of construction had degraded in some spots. The contractor removed the asphalt top-layer and needed a waterproofing membrane to apply to the exposed concrete deck beneath. The project required the removed top-layer be replaced with concrete, so the membrane needed to be tough and durable. The membrane was also required to not damage or degrade asphaltic rubbers because the rest of the parking surface was asphalt.

Product(s)/Solutions Provided:

The contractor ultimately decided on Hydralastic 836 with the Reinforcing Fabric HCR supplied by Form & Build Supply. This versatile, single-component waterproofing compound is applied cold. It skins over in as little as 30 minutes and can be applied straight out of the pail, saving time and simplifying its application. When used in conjunction with the Reinforcing Fabric HCR, the membrane can span minor cracks in the substrate’s surface and achieve a higher overall strength.

The contractor was able to easily apply the membrane to the concrete substrate and

up the sides of the surrounding asphalt layer thereby ensuring an impermeable waterproofing solution. From product education right through to application, Form & Build Supply was there to ensure a seamless contractor experience. Our sales staff is ready to help provide solutions so that you can get the job done right. If you’d like to learn more, email Keith Armstrong, here!