Projects

Earl Turcotte Waste Transfer Facility

Effort Trust

Innovation Hub

Miller Peppel Stone Transfer Station Whitby

Press Pit

TTC McNicoll

Waterloo Memorial Recreation Complex

Garage Restoration – 50 Queen Street, Kitchener

Jacob’s Retirement Home Beamsville

Kiwanis Pool

Loblaws Restoration

MTO 2017-3029 – Scotland Drive Bridge Repairs

AVRIL Building

Bridge # 7 Rehabilitation

Caledonia Mill

Galt Wastewater Treatment Plant

Jacob’s Retirement Home Beamsville

NRC

Oxford County Sewage Pumping Station

Piller’s Brantford

Riverside Exhibition Centre

Galt Wastewater Treatment Plant

Nature Fresh

New Beverly Central Elementary School & COH Community Centre

Whitby Health Centre

Copper Road Salt Dome

Dundas Street Reconstruction

Garage Restoration – 50 Queen Street, Kitchener

Kettle Creek Public School

The Gaslight Condos

Innovation Hub

Job Name: Linmar Innovation Hub

Contractor: Newton Group/ Tri Con Haid Concrete Finishing Ltd.

Owner: Linmar

Engineer/Architect: Tacoma Engineers

Background:

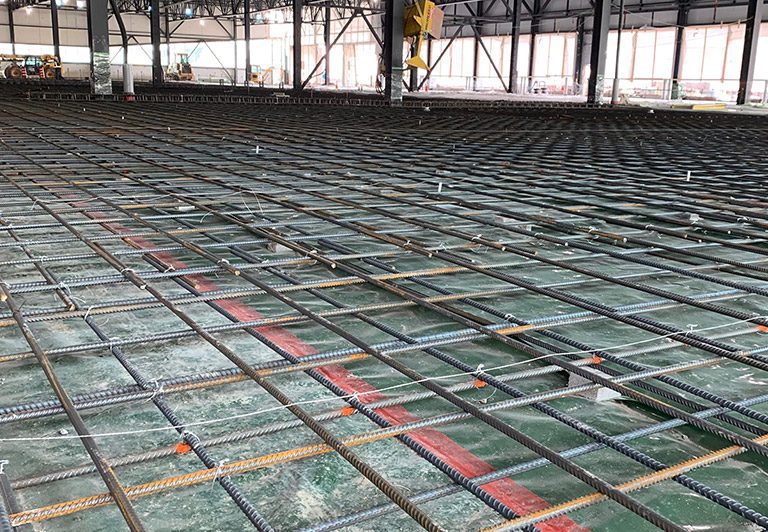

To build on its vision of cutting-edge manufacturing, Guelph-based Linamar recently constructed the Linamar Innovation Hub. From conception through to design and build, the facility needed to accommodate the dynamic nature of the company’s business. Research, development, and contract-manufacturing require a facility that can withstand constant re-tooling and rearrangement of heavy equipment. This created the necessity for a particularly resilient concrete floor.

Product(s)/Solutions Provided:

To create a durable, abrasion-resistant floor, Form & Build supplied Hard-Cem manufactured by Kryton. Hard-Cem is an Integral Hardening Admixture (IHA) that has the ability to at least double the wear life of a concrete pad. This makes it an ideal choice for a number of applications including industrial, transportation, marine, and many more. Essentially, wherever there are high-loads and abrasion-inducing activities, Hard-Cem will protect your concrete investment.

For this project, the following benefits also helped the customer feel confident in their choice of floor hardener:

• Consistency – Hard-Cem provides uniform hardness throughout the entire slab.

• Labour Savings – Hard-Cem is batched either at the concrete plant or at site whereas traditional shake-on hardeners must be applied after the pad is poured.

• Rust-Resistant – Unlike other metallic/fibre based hardeners considered for the project, Hard-Cem will not rust in the areas around the exterior doors of the facility.

Concluding Remarks:

Every day at Form & Build we enjoy the opportunity to build trust and form loyalty with the people who build our communities. Do not hesitate to reach out to any one of our six branches to inquire about how we can help you on your next project. If you’re an Engineer or Contractor interested in what Hard-Cem can do for you, click here to request a Lunch-and-Learn. Or get in touch with Joe Taylor to learn more, here.