Projects

Earl Turcotte Waste Transfer Facility

Effort Trust

Innovation Hub

Miller Peppel Stone Transfer Station Whitby

Press Pit

TTC McNicoll

Waterloo Memorial Recreation Complex

Garage Restoration – 50 Queen Street, Kitchener

Jacob’s Retirement Home Beamsville

Kiwanis Pool

Loblaws Restoration

MTO 2017-3029 – Scotland Drive Bridge Repairs

AVRIL Building

Bridge # 7 Rehabilitation

Caledonia Mill

Galt Wastewater Treatment Plant

Jacob’s Retirement Home Beamsville

NRC

Oxford County Sewage Pumping Station

Piller’s Brantford

Riverside Exhibition Centre

Galt Wastewater Treatment Plant

Nature Fresh

New Beverly Central Elementary School & COH Community Centre

Whitby Health Centre

Copper Road Salt Dome

Dundas Street Reconstruction

Garage Restoration – 50 Queen Street, Kitchener

Kettle Creek Public School

The Gaslight Condos

Beer Store Distribution Centre

Job Name: Beer Store Distribution Centre

Contractor: Maple Reinders

Owner: The Beer Store

Engineer/Architect: Maple Reinders

Background:

To augment their capacity, the Beer Store undertook the building of a new distribution centre in Caledon, ON North West of Toronto. The 407,000 square foot LEED-certified facility will be capable of storing 2.8 million cases of beer at any one time. Construction of the single level warehouse was entrusted to Maple Reinders, a firm known for quality, reliability, and on-time delivery.

Product(s)/Solutions Provided:

To ensure the quality of the concrete foundation work, Maple Reinders turned to Form & Build Supply.Form & Build was able to provide Dupont SM 50 mm rigid insulation to insulate the entirety of the building foundation. Dupont rigid insulation is a high-quality, extruded polystyrene foam insulation board that protects foundation walls from dampness and the damage from the freeze-thaw cycle.

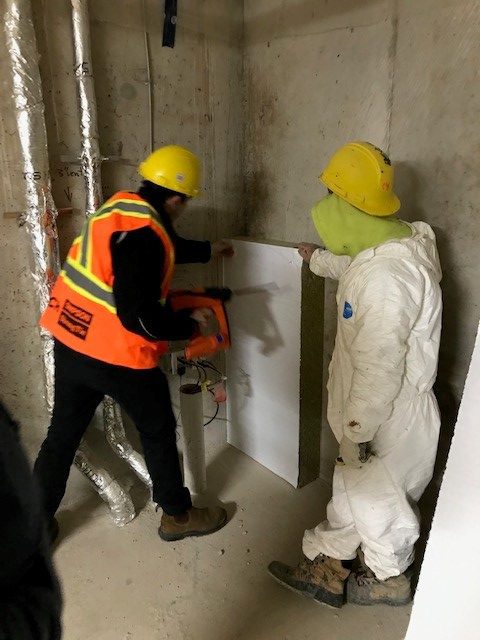

Originally, the insulation was to be fastened to the foundation using a trowel-applied insulation adhesive.To help expedite this laborious process, Form & Build suggested the Ramset Insulfast T4 System be used instead. The system consists of the automatic Insulfast tool and Insulfast fasteners. With the ability to shoot up to 1,000 fastener pins per hour, the lightweight Insulfast tool enables workers to affix insulation at a rate four times faster than traditional methods.

The feedback from the site after adopting the system supplied by Form & Build was almost immediate and overwhelmingly positive. The general sentiment from the jobsite was that the Insulfast tools and fasteners were the best purchase they’d ever made and resulted in big savings of both

time and money. Whether the job is big or small, Form & Build Supply strives to supply you with the things you need to get the job done. If you’d like to learn more, you can contact Mike Brown, here.