If you have ever driven under the elevated portions of the Gardiner Expressway in Toronto, you probably noticed the litany of rust stains and exposed rebar visible on many of the expressway’s concrete support columns. These are the product of a structurally damaging process called corrosion.

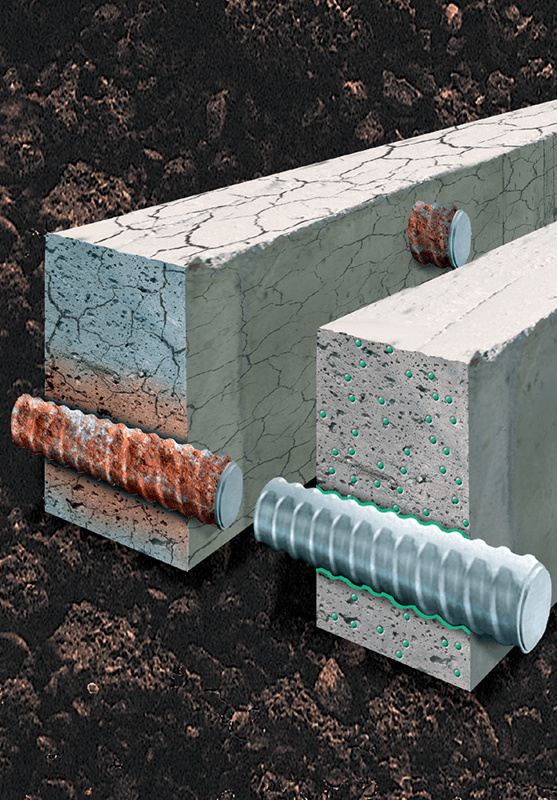

Corrosion occurs when chlorides – primarily from de-icing salts in colder climates – penetrate concrete and reach the steel reinforcement causing it to rust. The volume of rust exceeds that of steel and over time, causes the surrounding concrete to crack and become damaged.

The safety implications of this process are apparent. You can google ‘concrete falls from Gardiner’ and find stories about chunks of concrete breaking off and falling on the roadways below. It’s easy to understand that this continuing deterioration is slowly compromising the integrity of the structure. To combat this problem, the City of Toronto has allocated $2.2 billion to fund the elevated expressway’s repair cycle over the next 10 years. This means that this cycle of repairs will cost 20 times what it cost to actually build the Gardiner in the first place.

So if corrosion jeopardizes safety, deteriorates structural integrity, and costs structure owners exorbitant repair costs, what is the solution?

Old Solutions versus New

For years, Calcium Nitrite-based admixtures have been the conventional concrete additive to accomplish this function. However, Calcium Nitrates have numerous drawbacks that forming contractors, ready-mix plants, and owners have worked around due to the simple fact that no viable alternative existed.

Here at Form and Build Supply, we constantly search for new, innovative products to bring to market. Products that perform better and solve problems. We’re proud to say that when it comes to corrosion-inhibiting technology we have found a superior alternative to Calcium Nitrites in the form of Cortec MCI® 2005 NS. This admixture product is integrated into concrete during the mixing stage and works to protect the embedded rebar from corrosive elements.

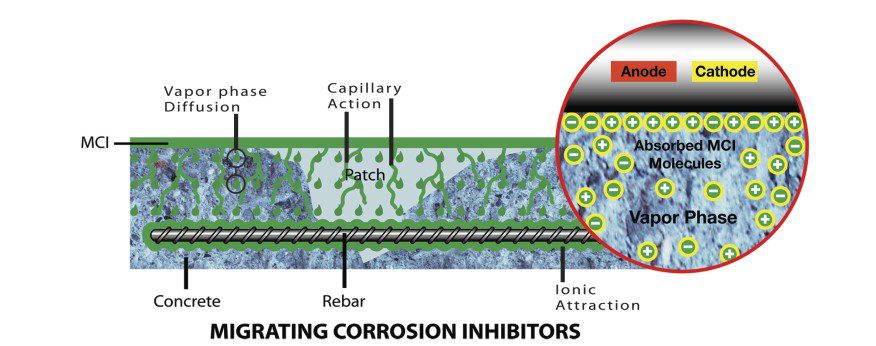

MCI® stands simply for Migrating Corrosion Inhibitors. This patented technology is incorporated into many of Cortec’s products and works by migrating through the concrete. When MCI® comes in contact with the embedded reinforcing steel, it has an ionic attraction and forms a protective molecular barrier around the steel. This barrier prevents corrosive elements from attacking the steel and greatly extends the concrete service life (see video for visual depiction of this process). Studies show that MCI® treated concretes have a corrosion rate that is 5 times lower than that of untreated concrete.

Benefits of Cortec MCI® 2005 NS versus Traditional Calcium Nitrites

For Calcium Nitrites to be effective, they require a large dosage rate to the concrete. This large dosage rate along with the nature of the product itself creates a number of problems for not only structure owners but concrete contractors as well. MCI® 2005 NS is the best solution to overcoming these challenges as illustrated below.

- Calcium Nitrites are Accelerators, Lower Air Content, and Increase Shrinkage Cracking: Due to their exceptionally high-dosage rates, Calcium Nitrites adversely affect concrete’s physical properties. Setting acceleration is one of these drawbacks and greatly reduces the amount of working time of the concrete. Forming contractors often experience quick or flash sets when using Calcium Nitrite dosed concrete in warmer weather. Calcium Nitrites also lower the air content in concrete which ultimately affects its durability. To offset these challenges, one must spend more money to add retarder and air-entrainment agents into the concrete mix. Additionally, Calcium Nitrates cause more concrete shrinkage which results in more cracking. This necessitates repairs on brand new structures. These headaches are avoided by simply switching to Cortec’s MCI® 2005 NS. It provides enhanced corrosion protection without affecting the set time or air content of your concrete.

- Calcium Nitrites require High Dosage Rates: For Calcium Nitrates to be effective they must be dosed at a substantially higher rate than Cortec MCI® 2005 NS. A lot of specifications provide for a Calcium Nitrate dosage rate of between 10 to 30 L/m3. In Ontario, there is a need for higher dose of Calcium Nitrites due to the above average presence of corrosive agents in the environment and extensive use of deicing salts in the winter. The higher dosage rate exacerbates problems previously mentioned. Cortec MCI® 2005 NS – on the other hand – is effective at a dosage rate as low as 1 L/m3 making it both more practical and cost effective.

- Calcium Nitrites Provide Inferior Long-Term Protection: MCI® stands for Migrating Corrosion Inhibitor. This describes how Cortec’s MCI® 2005 NS works. Its particles ‘migrate’ through the concrete structure and form a protective shield around concrete-embedded rebar. This shield protects the rebar from contaminants and reduces the corrosion rate by as much as 5 times versus untreated concrete. This ultimately extends the service life of the structure and reduces the number of required concrete repair cycles due to corrosion.

Already Enhancing Structures Worldwide

While MCI® 2005 NS and indeed, Cortec’s entire MCI®line of products are relatively new to the Ontario construction market, these products have been used in a number of high-profile jobs internationally. For instance, MCI® 2005 NS was used most notably in the podium substructure of the Burj Khalifa in Dubai – the tallest building in the world. The product was also used for a similar application in the Princess Towers also in Dubai.

MCI® 2005 NS’s use in this application represented 0.07% of the overall construction cost but effectively doubled the service life of the structure.

But the MCI® product line is effective in applications beyond towers and skyscrapers. Any civil application where the structural integrity of a concrete structure is vital can benefit from the use of the MCI® products. The Severn Bridge in the United Kingdom and the Cochrane Bridge in Alabama are two examples of where MCI® products were incorporated to protect the steel post-tensioned cables from corrosion.

Conclusion

Cortec’s line of MCI® products offer numerous benefits for anyone designing and building concrete structures. We’re proud at Form and Build to be the exclusive Ontario distributor for these products and look forward to talking with Engineers, structure owners, and concrete contractors about how this product line can enhance their structures and extend their service life.

To that end, we welcome anyone to reach out to us to schedule a lunch and learn or product demo. Please click here and enter your information and we will happily reach out to schedule a time to further discuss the benefits of our Cortec MCI® product line.